In the midst of all the custom watercooling excitement this year, Thermal Grizzly is launching a range of fittings and adapters. The range is ambitious and comprehensive. But the market is already dense and the competition tough! To get a clear idea of the range’s potential, we decided to put it to the test in an extremely demanding build . The verdict?

The test configuration

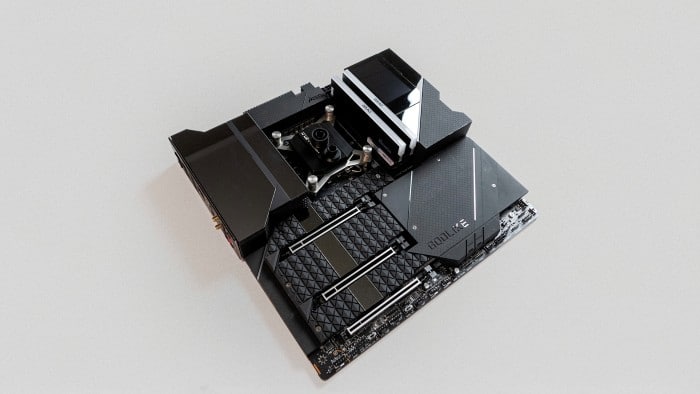

There’s nothing like an ambitious configuration and an oversized PC to test a range that aims to be premium and carry the Thermal Grizzly brand image. Some of you were able to discover the configuration live and help define the custom loop. For the others, here are the details:

- Kompcase Apex chassis

- MSI Godlike Z690 motherboard

- CPU intel core i7 12700KF

- GPU Asus ROG Strix RTX 4090

- RAM Biwin Black Opal DW100 DDR5 RGB

- SSD Biwin NV7400

- Power supply Seasonic Vertex GX-1200

- Heatkiller (CPU) and Optimus (GPU) waterblocks

- Corsair XR7 480mm and Alphacool Monsta + XT45 360mm heat sinks

- Singularity Computers Protium 2.0 tanks

- Thermal Grizzly fittings and adapters (full range)

- Monitoring 12v2x6 Thermal Grizzly Wireview Pro Reverse

The beast is full of superlatives, and the watercooling circuit is certainly out of all proportion. But what better opportunity to test the whole Thermal Grizzly range in one go!

Thermal Grizzly Fittings: the range in detail and in practice

ST16 fittings:

These are designed for 10/16mm inner/outer tubes, the most widely used. The first thing to note is that the grip without the clamping ring is about average. Some brands do better in this respect. Here, there’s just one ring, where there are sometimes two (or even three). On the other hand, once the ring is in place and tightened, the grip is perfect. You can even (but why?) pull on the tube quite firmly. Nothing moves. The ring itself is small and does not protrude beyond the base of the fitting. This choice offers welcome versatility, even in confined spaces.

For fans of sleeving (the technique of covering the tube with a coloured sheath popularized by LiquidHaus), the ST16 lends itself well to the exercise despite its reduced dimensions. A tour de force in which the single ring seen above plays a key role. No sleeving on this build, but we tested it live and will include it in the next build: we promise!

HT16 fittings:

Rigid tubes this time with an external diameter of 16mm. The first thing that stands out is that the outer ring is the same as for the ST16. They are, in fact, interchangeable. Practical, but above all aesthetically brilliant and consistent with the brand’s image. The footprint is exactly the same as the ST16: 21x14mm. On opening, you’ll discover a nicely sized gasket and a flat surface for the tube! It’s a daring choice, and one that can be disconcerting. But it’s so easy to use! Precise measurement of rigid tubes becomes a formality. Fans of perfect alignment will love it.

Rotary adapters:

The 90-degree rotary adapter is a classic in custom watercooling. Used for practicality or aesthetics, they are frequently found. Thermal Grizzly offers two: one standard and one T (1 inlet for 2 outlets). Their dimensions are almost identical to those of the ST16 and HT16 fittings. They, too, are designed for versatility and Small Form Factor applications . In fact, they are low-profile, with a height of less than 21mm. As with the rest of the range, they are tightened with an 8mm hex key. Aesthetic feature: once tightened, a cover with the range’s logo conceals the maneuvering point. In use, they stand out for their ease of installation, even on an already assembled radiator (see video below).

Extenders and plugs:

Thermal Grizzly offers a series of rigid extenders: 7, 10, 14 and 28 mm. No visible branding, sober, black, dimensions exactly compatible with fittings. They do what’s expected of them: simplify tube routing and make you forget about them. It’s worth noting, however, that their dimensions owe nothing to chance. Combined with the rotary adapters, they create useful combinations and offsets.

Last but not least, the plugs feature the range’s logo and design.

Verdict on use

To say that this build was demanding would be an understatement. The open configuration allows all sorts of overflow, but the density of the installed hardware complicates tube routing. We also chose to mix flexible and rigid tubes, to multiply the improbable angles and to make the loop infinitely complex. Thermal Grizzly fittings had the difficult task of tying this mishmash together into a coherent whole. Mission accomplished?

Without a second thought: yes. We simply can’t fault this new range in use. Of particular note is the ease of use of HT16 fittings. In addition to simplifying tube measurement, they enable the fitting to be installed and tightened just after a bending zone. We can see below that we connected one a few millimeters after bending, without any difficulty or sealing problem. We also like the way the components in the range interact and combine with each other. The look is a personal matter, but we love it.

Finally, what’s missing from the range? Initially, we’d like to see fittings for other tube sizes, especially rigid. Then, a few more adapters (45 degrees, drain, etc.). It seems unrealistic to imagine another choice of color, but who knows. The simplicity and consistency of this range is a strength. Over-complicating it seems irrelevant.

Fittings are available on the Thermal Grizzly website.

More photos and videos on the networks.